INTRODUCTION

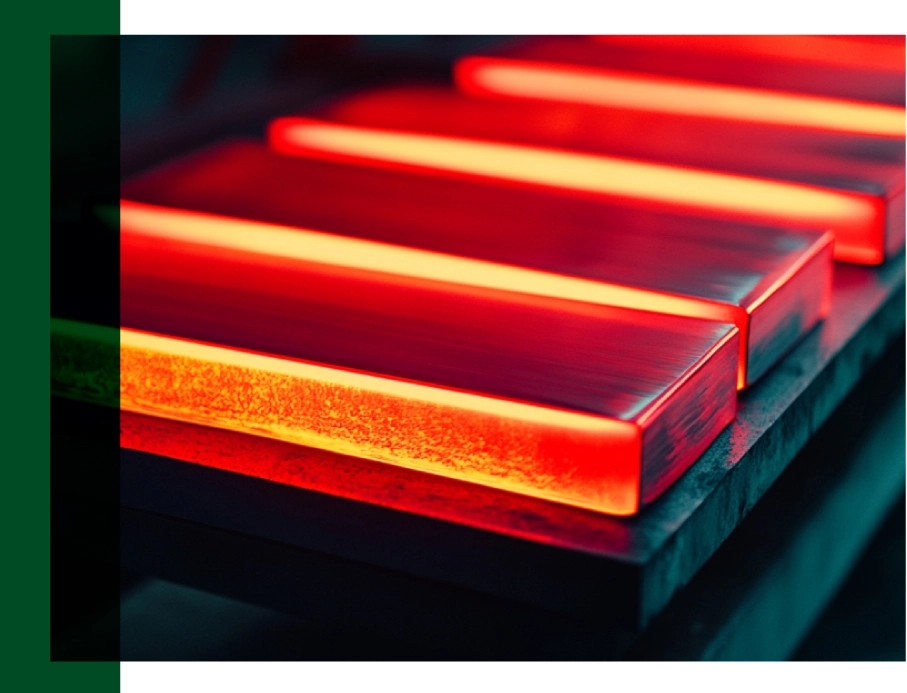

The Melt Shop, located in Johannesburg, is a steel mill specializing in the production of billets. These billets serve as raw material for major metal processors producing bars, rods, and wire. With cutting-edge technology, a skilled workforce, and a strong commitment to environmental and operational excellence.

RECEIVING & PRE-PROCESSING

The production process at The Melt Shop begins with the receipt of scrap metal. We have developed a robust system capable of charging scrap in various forms, such as industrial or production waste, obsolete plant and machinery, and various obsolete scrap metal. Upon arrival, materials are offloaded into designated receiving bays equipped with overhead cranes and heavy equipment, ensuring efficient handling of these materials. These bays are organized to maintain a steady supply for subsequent production stages.

Pre-processing involves an initial inspection to remove non-ferrous contaminants, tramp elements and oversized items, optimizing material flow and preparing the scrap for charging into the melting furnace.

RAW MATERIALS

We utilize scrap steel raw material in our process, sourced from South Africa and neighboring countries. With an established procurement and infeed capacity, we ensure a steady supply of high-quality materials to support our production demands.